"Easy" transition to a fully SAP-integrated DMS

“Easy” transition to a fully SAP-integrated DMS

The transition to SAP S/4HANA is on many minds in global IT departments. The project is complex, and the timeline is tight: support for SAP ERP Central Component (ECC) will end in 2027.

One major challenge is document management (DMS). Until now, Easy DMS was the solution of choice for many companies. Fully integrated into the SAP standard, it allowed documents to be managed across the enterprise in a structured manner. However, Easy DMS will no longer be supported with the migration to S/4HANA. So how can documents be managed securely and efficiently in the future?

With its migration to the new ERP generation, Bayern-Chemie opted for the SAP add-on smart-plm [documents] from smart-plm Aigner GmbH & Co. KG for document management. The DMS uses the same data structures and objects as Easy DMS for representing folder structures, documents, and document versions, and is likewise fully integrated into SAP.

This eliminates the need for an extensive data migration, allows the existing authorization concept to be retained, and makes the transition to the new DMS “easy.”

The challenge

Over 250 employees operate on the 110-hectare site. Production is characterized by extended development periods for products with long life cycles, generating a correspondingly high volume of documents that must be managed in software. Moreover, the company’s safety-critical products are subject to strict documentation requirements with long retention periods. For many years, document management was handled via SAP Easy DMS.

Integrated directly into Windows Explorer as an add-on, it linked documents with SAP objects such as technical locations, material masters, or projects, enabling centralized management of numerous document types across departments.

“With increasing data volume, performance was no longer satisfactory,” reports Karl Hofbauer, Senior SAP PLM Consultant at smart-plm Aigner and direct contact person for Bayern-Chemie. Since Easy DMS is no longer supported for the upcoming S/4HANA transition, a suitable alternative needed to be found.

The solution

Requirement: Fully SAP-integrated successor to Easy DMS

Bayern-Chemie had already successfully collaborated with smart-plm Aigner on a project for storing production documentation, by developing a solution linking documents to production orders and serial numbers, thus, enhancing the functionality of Easy DMS.

Meanwhile, smart-plm Aigner had launched a new solution: smart-plm [documents], fully integrated into SAP and using the same data structures and objects for folder structures, documents, and document versions as the proven, but soon-to-be-retired, DMS. This enabled a smooth and rapid implementation without the need for data migration.

“Shortly after deploying our add-on into Bayern-Chemie’s SAP system and performing basic customizations, the existing folder structures and documents were immediately visible and usable in our solution,” explains Karl Hofbauer. Another advantage for the IT department was that no separate software installation with dependencies to different operating system versions was required, minimizing future maintenance efforts. Thanks to the open and customer-centric software architecture of smart-plm [documents], it was also possible to integrate and fully replicate Easy DMS functionality, including company-specific enhancements.

Outcome: one-to-one DMS replacement with added value

Today, approximately 70 users across departments work with the new document management system at Bayern-Chemie. The smart-plm [documents] interface follows the familiar Windows Explorer look & feel, enabling quick and intuitive handling. Convenience features such as drag-and-drop for moving documents and an integrated document viewer make adoption even easier. The reduced training effort facilitated rapid acceptance.

The existing authorization concept could also be fully retained, ensuring that only employees authorized for a project or specific product have access to the relevant documents. The new DMS also supports workflows, allowing documents to be directed with simple review and approval processes within the organization. Shortly after transitioning to the new system, a follow-up project was initiated to implement document management in the plant maintenance department based on smart-plm [documents].

“Bayern-Chemie generates a high volume of plant maintenance documentation, which until now was poorly traceable and stored on network drives without links to relevant SAP objects, as Easy DMS could not support a structured filing system,” Karl Hofbauer describes.

Expansion: plant maintenance records reflect organizational structure

The full lifecycle management of technical assets and buildings—from planning to inspections, maintenance, repairs, and decommissioning—is the responsibility of plant maintenance. Hierarchical asset and building structures are represented in SAP via technical locations and equipment hierarchies.

To enhance document management in this complex environment, new document types were defined for the introduction of “plant maintenance records”: building information (e.g., object data, construction permits), plans and photos, AGU documents (e.g., fire protection, occupational safety) for technical locations, as well as various protocols and technical data sheets for equipment. Template folder structures were established for technical locations and equipments, which are automatically linked to newly created objects. This enables users to create and view documents directly within the maintenance object in pre-configured folder structures.

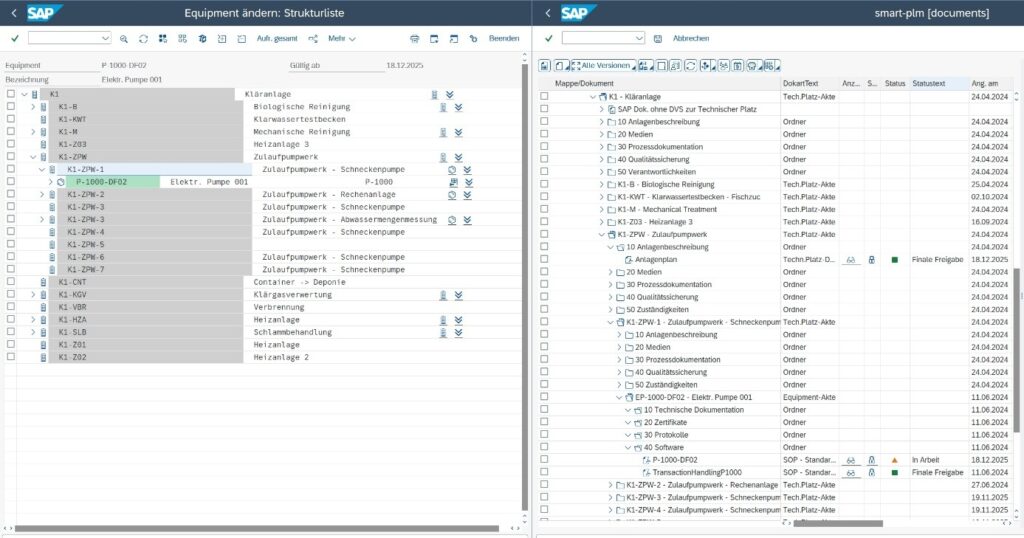

>> Symbolic image: on the left, the IH structure list; on the right, the synchronised file structure in smart-plm[documents]

“This approach allowed us to map the company’s complete structure from the plant level, to buildings, floors, and offices down to individual cabinets and drawers,” explains the consultant from smart-plm Aigner GmbH & Co KG. An automatic synchronization function ensures that changes in the plant maintenance structure, such as equipment removal and reinstallation, are reflected in the record structures. Integration into the maintenance process allows users to manage documents directly within each maintenance object.

Bulk upload functionality enables multiple documents, such as inspection reports, to be automatically placed into target folders of various equipment records according to customer-specific logic, eliminating manual uploads. If a document already exists, a new version is created, and the previous one is marked obsolete.

“Documents are finally easy to find, stored in a structured manner. There is no more searching through network drives with access requests or documents stored on individual clients,” describes a key user.

Conclusion

Future-proof: supplier records for greater procurement transparency

The successful collaboration with smart-plm Aigner lays the foundation for future projects. “We maintain an ongoing exchange with Bayern-Chemie in an atmosphere where everyone feels well supported,” says Karl Hofbauer. The future-proof architecture of smart-plm [documents] offers potential for further optimizations, with no complex interfaces or client dependencies to manage, saving time and enabling continued improvements.

“Following the successful implementation of maintenance files, we are already considering the introduction of supplier files, prompted by procurement needs,” he adds. This will follow the complete transition to SAP S/4HANA, which also involves restructuring procurement and sales, introducing business partners, and consolidating suppliers and customers. “There is no standard supplier record in SAP; Bayern-Chemie previously managed standard documents linked to suppliers as document info records,” Hofbauer explains.

For better usability and traceability, the company intends to leverage the adaptability of smart-plm [documents] in close collaboration with the IT experts for the new ‘easy’ DMS.